Inspeção pré-embarque (PSI) para controle de qualidade antes do envio

Certifique-se de que seus produtos atendam aos seus requisitos antes que a produção seja finalizada e seus produtos sejam embalados para envio.

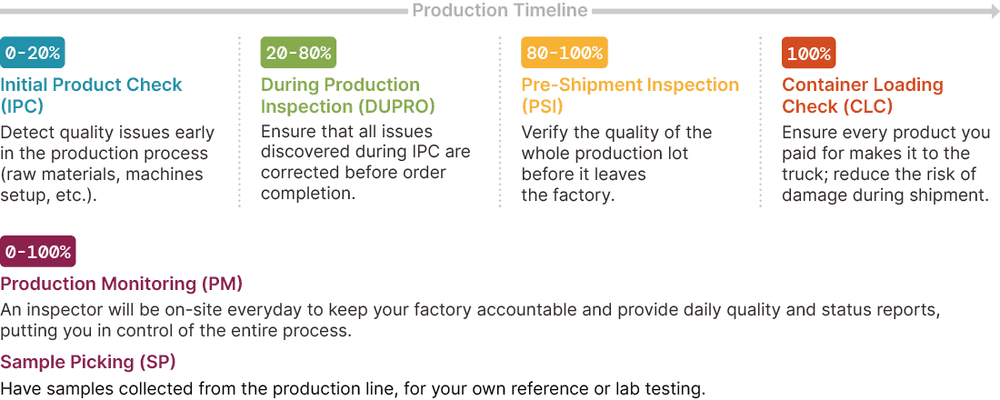

A inspeção pré-embarque da QIMA é um exame intenso no local realizado quando 80% do seu pedido de produção estiver concluído. Nosso serviço ajuda a verificar se seus produtos atendem a todas as especificações exigidas, permitindo que você tome medidas corretivas antes que sua ordem de produção seja finalizada.

Saiba mais sobre:

O que é uma Inspeção pré-embarque (PSI)

Por que você precisa de uma inspeção pré-embarque?

Quais verificações são realizadas?

Inspeção Pré-Embarque (PSI) da QIMA

O que acontece depois que uma PSI é concluída?

Experiência em QIMA

Benefícios do QIMA

Entre em contato conosco para obter preços

O que é uma Inspeção pré-embarque (PSI)?

Uma inspeção pré-embarque garante que seus produtos atendam às suas especificações de qualidade antes de serem enviados. Quando pelo menos 80% do seu pedido estiver concluído, um inspetor visita a fábrica e utiliza processos padrão do setor para revisar e testar abrangentemente seu produto. Você receberá um relatório completo, acessível através de nossa plataforma online.

Precisa de mais informações?

Ao entrar em contato com a QIMA, você concorda com a nossa política de privacidade e com os nossos termos e condições.

Por que você precisa de uma inspeção pré-embarque?

As inspeções pré-embarque realizadas por uma terceira parte neutra são um padrão da indústria para garantir que seu produto atenda às suas especificações de qualidade. Produtos defeituosos ou de qualidade inferior podem levar a reclamações de clientes, devoluções, perda de vendas e danos à reputação da sua empresa.

Com nossa inspeção antes do despacho, você fica tranquilo de que seu pedido foi corretamente cumprido antes do envio.

Há várias razões para utilizar nossa PSI:

Certifique-se de que seu fornecedor atendeu a todas as especificações acordadas: Isso ajuda a evitar mal-entendidos e garante que os produtos entregues sejam exatamente o que foi solicitado.

Verifique os padrões de qualidade com listas de verificação padrão ou personalizadas: Listas de verificação personalizadas podem ser adaptadas às suas necessidades específicas com base em seus critérios únicos.

Verifique o progresso da produção: Identifique quaisquer atrasos antes que impactem seu cronograma de entrega.

Tome medidas corretivas antes que seja tarde demais: Implemente soluções rapidamente, minimizando as interrupções na produção e no envio.

Previna devoluções e proteja a imagem da sua marca: Garanta a qualidade antes do envio, reduzindo a probabilidade de reclamações e devoluções de clientes.

Verifique a qualidade do produto final quando não puder acessar a fábrica pessoalmente: Com nossa PSI, você pode manter a garantia de qualidade sem estar fisicamente presente.

Não é uma boa ideia confiar na sua fábrica para informar que os produtos atendem a todas as especificações. Nossos especialistas em PSI fornecerão uma avaliação imparcial e abrangente do seu pedido de produção.

Quais verificações são realizadas?

Primeiramente, o inspetor do QIMA selecionará aleatoriamente uma amostra de produtos para inspecionar, seguindo o padrão de amostragem ANSI/ASQ Z1.4-2008.

Após a seleção da amostra, as inspeções são adaptadas para atender às necessidades dos clientes e produtos específicos.

Fornecemos uma variedade de listas de verificação de inspeção pré-projetadas adequadas para diferentes produtos, que você pode usar "como estão". Você também tem a opção de modificar essas listas adicionando verificações específicas ou pode desenvolver uma lista completamente nova que atenda aos seus requisitos específicos.

Inspeção pré-embarque (PSI) da QIMA

A QIMA realiza uma inspeção pré-embarque abrangente que envolve uma série de verificações meticulosas, normalmente incluindo o seguinte:

Verificações das especificações do produto:

Quantidades de produtos semiacabados, acabados e embalados

Cores do produto, estilo, construção

Arte-final, incluindo ortografia, fontes, dimensões, posicionamento e design geral

Etiquetas, incluindo etiquetas principais, etiquetas de cuidados, etiquetas de tamanho e etiquetas de produtos

Outras verificações e testes específicos do produto

Teste funcional

Análise da composição do material

Outros testes relevantes

Verificações de defeitos de mão de obra

Verificação de defeitos

Verificação do processo de montagem

Consistência em todos os produtos

Verificação das dimensões do produto

Comprimento, largura, altura

Verificação de peso unitaire

Verificações de embalagem e empacotamento::

Embalagem interna e externa das unidades

Dimensões e pesos da caixa de exportação

Marcas de remessa nas caixas de papelão

O que acontece após a conclusão de uma inspeção pré-embarque?

Uma vez que a inspeção pré-embarque é concluída, você receberá um relatório de inspeção detalhado no mesmo dia. Você poderá acessar facilmente o relatório através de sua conta online do QIMA. O relatório detalha os achados da inspeção, inclui fotos de quaisquer defeitos e fornece uma avaliação geral de aprovação/reprovação.

Experiência em QIMA

A QIMA oferece controle de qualidade independente, projetado para proteger seus interesses comerciais. Nossos inspetores altamente treinados e experientes são especialistas em produtos que recebem treinamento regular em suas áreas de especialização. Eles podem estar em sua fábrica dentro de 48 horas após a reserva e fornecer o relatório no mesmo dia da inspeção.

Nossas inspeções cobrem uma gama completa de produtos de consumo, incluindo, entre outros, vestuário, calçados, brinquedos, eletrônicos e móveis.

Crie uma conta e reserve uma inspeção pré-embarque (PSI)

Leve seu gerenciamento de qualidade para o ambiente on-line

O QIMA oferece uma plataforma on-line inteligente para ajudá-lo a gerenciar perfeitamente seu controle de qualidade e sua rede de fornecimento global.

Você pode facilmente agendar, cancelar ou reprogramar inspeções, fazer pagamentos ou baixar seus relatórios de inspeção com apenas alguns cliques. Também fornecemos um painel personalizável com todos os seus dados de controle de qualidade, para que você possa identificar tendências e tomar decisões informadas em tempo real.

Benefícios do QIMA

Controle de qualidade independente realizado por especialistas em produtos para proteger seus interesses comerciais.

Cobertura global em 100 países da Ásia, África, Europa, América do Norte e América do Sul.

Rapidez e flexibilidade com um inspetor no local em 48 horas; modificação ou cancelamento até o dia anterior à inspeção.

Relatórios de inspeção no mesmo dia, personalizados para o seu produto.

Gerenciamento de programas on-line para agendar inspeções, realizar pagamentos e baixar relatórios detalhados.

Painel de qualidade personalizado para identificar tendências e tomar decisões informadas em tempo real.

Classificado como #1 no setor em satisfação do cliente, com base em uma medição independente do NPS.